Westinghouse Opens Full‑Scale AP1000 Control‑Room Simulator in Madrid

Updated Published Cached

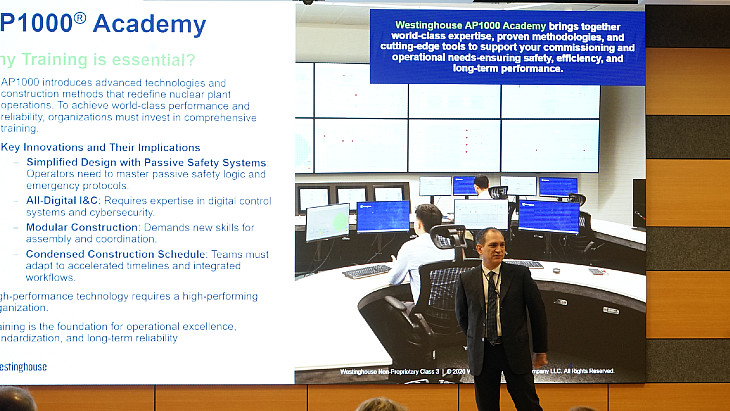

Westinghouse launches full‑size AP1000 control room replica in Madrid – The company opened a full‑sized control‑room simulator at a new AP1000 Training Academy in Spain, providing an environment identical to that of future AP1000 units for operator training and system testing [1].

Training begins five years before plant startup to build deep operator pool – Luca Oriani explained that operator training starts about five years prior to commercial operation, requiring enough qualified staff for 24‑hour, year‑round plant operation [1].

Spain chosen despite nuclear phase‑out; centre will serve all of Europe – Oriani said the Madrid location conveniently gathers experts from the United States and Central/Eastern Europe, noting that political debates may shift and Spain could eventually build new reactors, while the centre remains the Europe‑wide training hub [1].

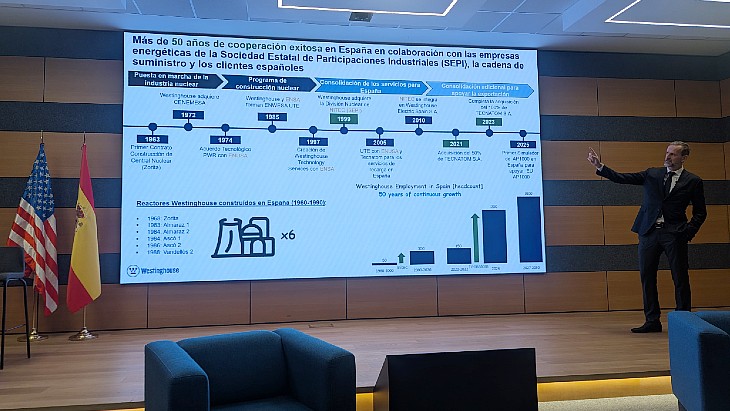

Westinghouse expects 300‑person staff increase in Spain by 2030 – Executives forecast headcount rising to roughly 1,500 employees in Spain, a growth that would persist even if scheduled Spanish plant closures proceed, reflecting the firm’s long‑term presence since the country’s first reactor [1].

AP1000 contracts span Ukraine, Poland, Bulgaria, India and potential Europe projects – Westinghouse holds signed agreements for nine units in Ukraine, three in Poland, two in Bulgaria, six in India, and is conducting front‑end engineering studies for additional European sites, indicating strong demand for the design [1].

Nth‑of‑a‑kind AP1000 cost projected at one‑third to one‑half of older designs – Oriani noted that, depending on site specifics, the standardized AP1000 could achieve a cost per megawatt between 33 % and 50 % of previous‑generation plants, thanks to fleet standardisation and modular construction [1].

- Luca Oriani – President of APX at Westinghouse Electric and global head of the new reactor business; discussed training timelines, staff retention, cost projections, and the strategic choice of Spain.

- Xavier Coll – Head of Westinghouse’s Spanish business; commented on the potential extension of Spain’s existing reactors and the energy implications of shutting them down.